In the product development stage, design issues are difficult to detect but easy to fix. Although it is easy to detect after product launch, the cost of repair is high. SKF can help you reduce total costs by shortening product development time and achieving the right design from the beginning.

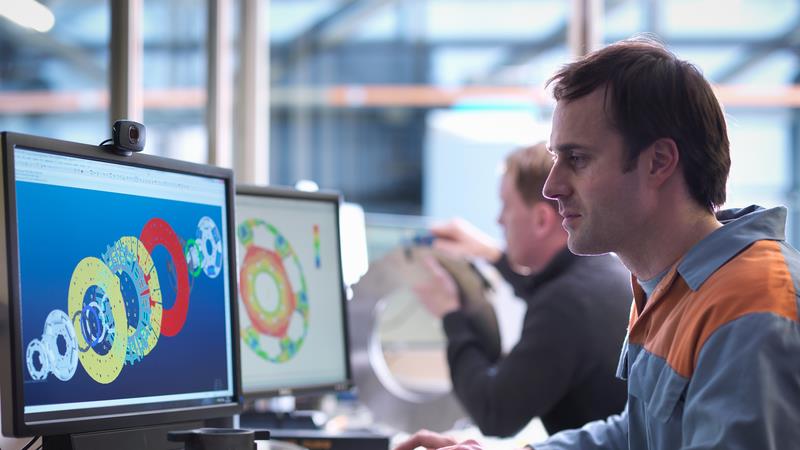

Our experts can improve or even replace expensive and time-consuming physical testing. We analyze new equipment, including bearings and all other machine components, during the design phase using software. These analyses can be used to determine the performance and reliability that need to be optimized. Our Six Sigma Design tool can assist you in concept selection and evaluation, as well as risk assessment techniques.

In addition, with advanced computing and simulation tools, we can increase your technical knowledge in the application field and reduce risks by identifying key Z and potential design improvements and optimizations for Z. We can handle complex designs and evaluate design parameters that are difficult to measure experimentally. These measures can minimize on-site testing to the greatest extent possible, helping your product to be launched to the market in a shorter period of time, reduce costs, and optimize performance.

Single row deep groove ball bearings are the most widely used type of bearing. Provide closed (with sealed or dust cover) or open design. Open type be...

Stainless steel deep groove ball bearings can resist corrosion caused by moisture and other media. Provide closed (with sealed or dust cover) or open ...

A single row deep groove ball bearing with a ball loading notch has a ball loading notch on both the inner and outer rings, which is used to load more...

Double row deep groove ball bearings are very suitable for use in bearing configurations where the load-bearing capacity of single row deep groove bal...

Copyright © 2002-2021 SKF Bearing Copyright Address:1-2F, Building 4, 1628 Lizheng Road, Lingang New Area, China (Shanghai) Pilot Free Trade Zone

Copyright © 2002-2021 SKF Bearing Copyright Address:1-2F, Building 4, 1628 Lizheng Road, Lingang New Area, China (Shanghai) Pilot Free Trade Zone