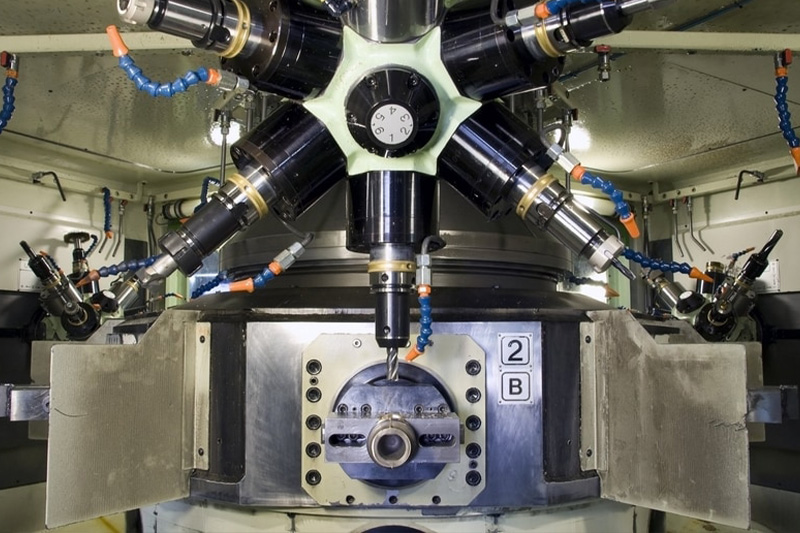

Increase productivity and reduce life cycle costs

Digitalization is driving new technologies in the machine tools industry. Although it hasn’t changed how machine tools are built, it’s certainly altered the way we think about production and how all operations are interconnected, enabling even further automation.

At SKF, we put a lot of focus on developing solutions that help increase reliability, raise production capacity and lower life cycle costs. We do this by monitoring critical assets to avoid unplanned stops – helping to move the industry towards proactive, condition-based maintenance. We also deliver solutions designed to extend service intervals and lower maintenance costs. All to increase the uptime of your machines.

Creating solutions for Industry 4.0 is a key focus area – incorporating machine learning, on-line systems, IoT platforms and related services. We are also collaborating with leading machine builders and control system suppliers, integrating our systems for next levels of automation.

Increase productivity and reduce life cycle costsDigitalization is driving new technologies in the machine tools industry. Although it hasn’t changed

View more

View more

Minimizing friction has been our cause for more than a century. SKF Super-precision angular contact ball bearings are carefully constructed using all

View more

View more

Copyright © 2002-2021 SKF Bearing Copyright Address:1-2F, Building 4, 1628 Lizheng Road, Lingang New Area, China (Shanghai) Pilot Free Trade Zone

Copyright © 2002-2021 SKF Bearing Copyright Address:1-2F, Building 4, 1628 Lizheng Road, Lingang New Area, China (Shanghai) Pilot Free Trade Zone