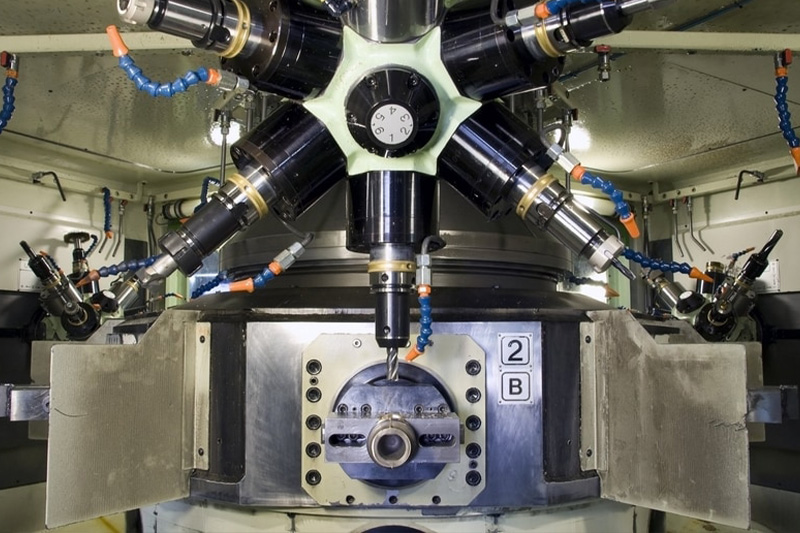

If CNC systems are the brains of the machine, the spindle units are the heart, and monitoring systems are the nerves. Keep them connected for smooth and reliable operation.

Optimize communication between CNC control and condition monitoring systems for excellent performance

In most types of machine tool processing, users are looking for a higher level of quality, increased uptime and sustainable solutions. Moving from time based- to condition based-maintenance reduces the total life cycle cost of the machine, and improves the performance and productivity in the production line.

By incorporating data from the machine’s CNC systems into the SKF IMx condition monitoring technology – end users will be able to predict spindle health using vibration, temperature, speed and process data. The data can be uploaded and integrated into SKF @ptitude Observer software, and then visualized for better diagnostics and prognostics – either at your maintenance department or at SKF dedicated centres. Remote Diagnostic Centres (RDC) and SKF Rotating Equipment Performance Centres (REP) can support with more in-depth analysis of the machine’s status and trends.

Increase productivity and reduce life cycle costsDigitalization is driving new technologies in the machine tools industry. Although it hasn’t changed

View more

View more

Minimizing friction has been our cause for more than a century. SKF Super-precision angular contact ball bearings are carefully constructed using all

View more

View more

Copyright © 2002-2021 SKF Bearing Copyright Address:1-2F, Building 4, 1628 Lizheng Road, Lingang New Area, China (Shanghai) Pilot Free Trade Zone

Copyright © 2002-2021 SKF Bearing Copyright Address:1-2F, Building 4, 1628 Lizheng Road, Lingang New Area, China (Shanghai) Pilot Free Trade Zone