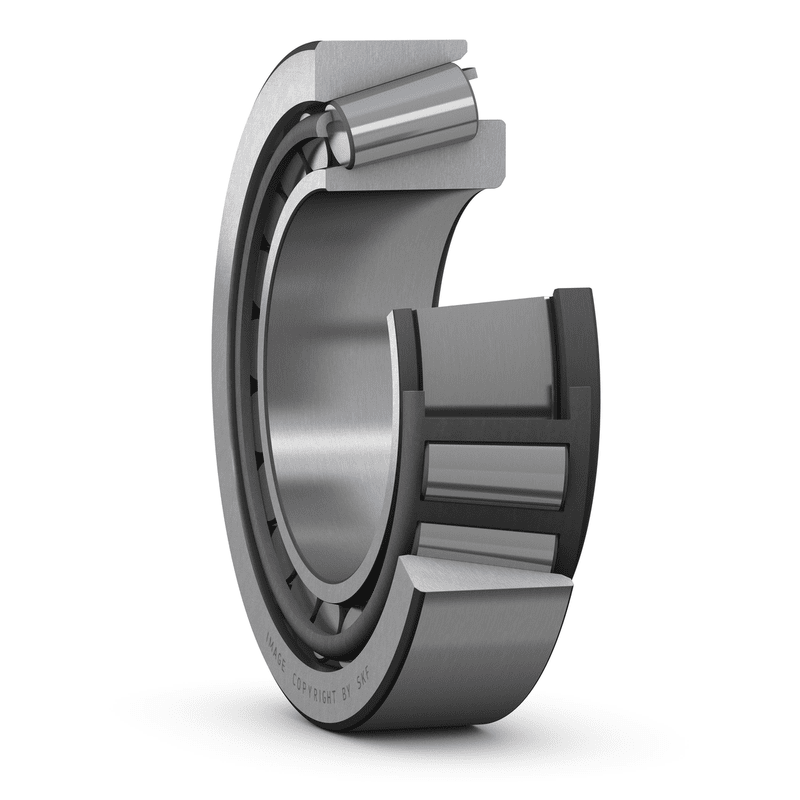

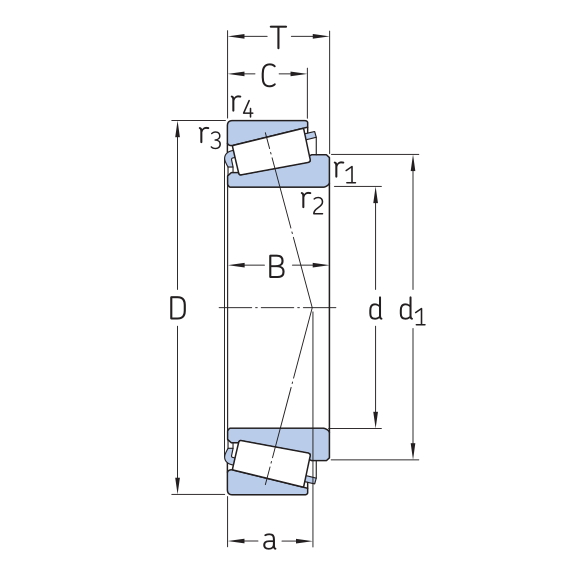

Single row tapered roller bearing

SKF single row tapered roller bearings are designed to accommodate combined loads, namely radial and axial loads acting simultaneously. The extension lines of the raceway intersect at the same point on the bearing axis to achieve true rolling, thus having low friction torque during operation. The axial load capacity of tapered roller bearings increases with the increase of contact angle α. The size of the contact angle (usually 10 ° to 30 °) is related to the calculation coefficient e (according to the product table): the larger the value of e, the larger the contact angle.

Characteristics and advantages

Low friction

The optimized roller design on the edge and the smoothness of the edge surface can promote the formation of a lubricant film, thereby reducing friction. This also reduces the heat generated by friction and edge wear. In addition, bearings can better maintain pre tension and reduce noise levels during operation.

Long service life

The basic design of SKF Explorer bearings includes a logarithmic raceway shape that optimizes the load distribution along the contact surface, reduces stress peaks at the end of the roller, and reduces sensitivity to misalignment and shaft deflection with conventional straight lines.

Improve operational reliability

Optimizing the surface treatment of the contact surface between the roller and the raceway is beneficial for the formation of a hydrodynamic lubricating oil film.

Consistency of roller profile and size

The roller manufacturing tolerances and dimensional accuracy integrated into SKF tapered roller bearings are extremely precise to the point where they are almost identical. This provides the optimal load distribution to reduce noise and vibration levels, and enables more precise pre tensioning.

Application of rigid bearings

A single row tapered roller bearing usually needs to be adjusted together with another tapered roller bearing. By applying a preload, rigid bearing applications can be achieved.

Running in phase with peak temperature decrease

Conical roller bearings usually have a running in period, during which conventional designed conical roller bearings experience significant friction, leading to wear. This impact will cause an increase in bearing temperature. Under the premise of accurate installation and lubrication of bearings, using SKF tapered roller bearings can significantly reduce friction, wear, and frictional heat.

Separable and interchangeable

The inner ring (inner ring component) with roller and cage assembly can be installed separately from the outer ring. In addition, separable components are interchangeable. This helps with installing, disassembling, and maintaining inspection procedures.

Copyright © 2002-2021 SKF Bearing Copyright Address:1-2F, Building 4, 1628 Lizheng Road, Lingang New Area, China (Shanghai) Pilot Free Trade Zone

Copyright © 2002-2021 SKF Bearing Copyright Address:1-2F, Building 4, 1628 Lizheng Road, Lingang New Area, China (Shanghai) Pilot Free Trade Zone